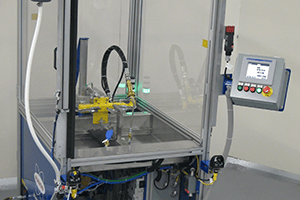

The Braze Mate is the ideal automated brazing machine for low volume applications or short runs of various part styles.

In production, an operator loads the part into a stainless steel fixture. A premeasured deposit of Fusion Paste Alloy is applied to the joint area with a hand-held applicator gun. As an option, this gun can be mounted to an automatic slide. The operator then activates dual, zero-pressure “touch” buttons, which initiates the machine cycle.

Automatically, a fixed pattern of gas/air burners advances into heating position. Oscillating flames eliminate “hot spots” at the assembly joint area. Once joining temperature is reached, the burner manifold retracts into idle position. A gradual air and water cooling sequence is followed by manual part inspection and final unloading. Depending on the application, 1 or 2 parts can be run each cycle.