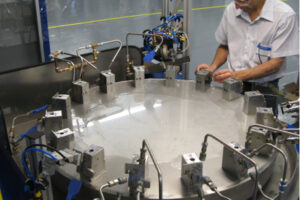

The Rotary Index style machine is the most widely used for most automated soldering and brazing applications. The typical sequence on a rotary machine begins with manual or automatic loading of parts onto fixtures. Indexing clockwise, the parts are pasted by one or more automatic applicator guns. These guns, generally mounted on slides, apply a premeasured deposit of paste alloy to each joint.

After pasting, the parts index again through a series of flame burners. The burners progressively heat the assembly to the liquidus temperature of the filler metal. Following heating, the part indexes through a series of cooling stations. Both air and water are used to solidify the alloy and bring the part and fixture back to room temperature. The finished part is then automatically ejected or manually unloaded by the operator. Production rates between 100-1200 parts per hour are typical.