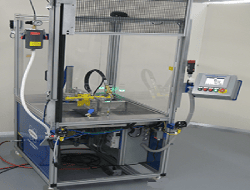

Braze Mate 100/150/200 Standard Features:

Our value propositions

-

Made in America

-

Reliable Customer Service

-

Over 90+ Years Experience

Braze Mate 100/150/200 Standard Features:

- Operator Station with PLC Interface makes part changes quick and easy while providing machine diagnostics for quick troubleshooting

- Quick-Disconnect manifolds require no tools to change making part changeovers quick and easy

- Heat manifolds are powder coated

- Fully adjustable manifold position makes machine configurable for most applications

- Gas Flowmeter and Manifold Manometer to verify process settings

- Heat, Air Cooling, and Water Cooling time adjustable through Operator Interface

- Needle Valves installed on all air and water cooling outlets

- Individual gascocks installed for each burner to allow individual flow adjustments or to turn burners on and off depending on part being processed

- Stainless Steel tubing used for burner pattern provides rigidity

- Guarding provides safety and process stability be shielding from air currents

- Polycarbonate windows allow for good visibility

- Banner Two-Hand safety switches assure operator is clear of machine

- All guard doors hinged for easy maintenance

- All utility connections located together

- Color-coded piping for gas lines, air lines, and water lines

- Air dump valve with lockout for main air supply

- Hi/Lo Heat System conserves fuel by switching to low settings between cycles

- Isolation valves installed on incoming air and fuel source lines

- Oscillating Heat Slide with adjustable stroke spreads heat throughout the joint area evenly

- Stainless Steel Water Trough

- Access Door for heat system adjustments

- Safety pressure switches on heat system detect low gas pressure, high gas pressure, and low air pressure

- Proximity switches installed on extend and retract positions of all slides

- Flow Controls installed on all cylinders and slides

- Air dump valves installed on all slides to assist with setups and adjustments

- Paste tanks supplied with quick-release lid clamps

- Paste guns controlled through the PLC to allow paste adjustment through the PLC

- Manual paste purge pushbuttons supplied for each paste gun

- 1 spare paste gun supplied for each paste gun used

- Free servicing of paste guns when Fusion paste products are used

- Allen-Bradley MicroLogix PLC with a MicroView Operator Interface

- 24VDC control voltage

- Quick Disconnect on proximity switches, pressure switches, and solenoid valves to make maintenance quick and simple.

- Leveling Feet

Additional BrazeMate 150/200 Standard Features:

- Heat slides include rotating motion to swing heat pattern into position, while keeping the burners up and away from the operator when retracted

- Overhead lighting keeps things visible for the operator

Additional BrazeMate 200 Standard Features:

- Two independent heat systems and heat manifold slides allow two completely different assemblies to be processed on the same machine, or one assembly with multiple joints to be processed using different heat process in two different areas.