Silver Brazing

Our value propositions

-

Made in America

Made in America

-

Reliable Customer Service

Reliable Customer Service

-

Over 90+ Years Experience

Over 90+ Years Experience

Silver Brazing

Silver brazing is a joining process whereby a non-ferrous filler metal, alloy is heated to melting temperature (above 800°F) and distributed between two or more close-fitting parts by capillary attraction. At its liquidus temperature, the molten filler metal interacts with a thin layer of the base metal, cooling to form an exceptionally strong, sealed joint due to grain structure interaction. The silver brazed joint becomes a sandwich of different layers, each metallurgically linked to each other.

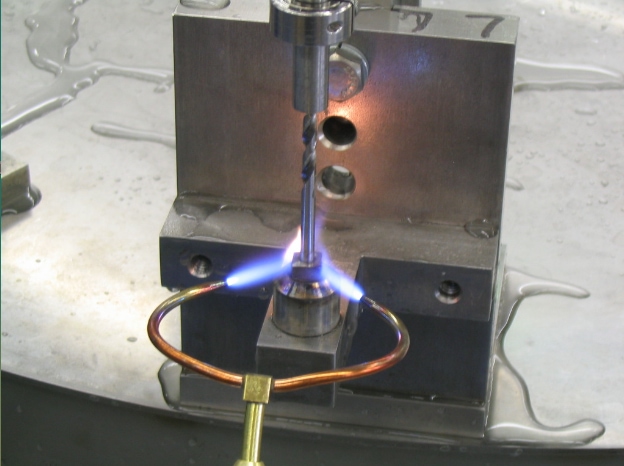

Silver brazing can employ various heat sources such as torch, flame, acetylene, gas/air, induction, resistance, infrared, oven, and furnace. Silver brazing uses filler metals and alloys such as silver, copper, zinc, cadmium, etc.

Flux is necessary for brazing to remove and prevent reformulation of surface oxides on the base metals.

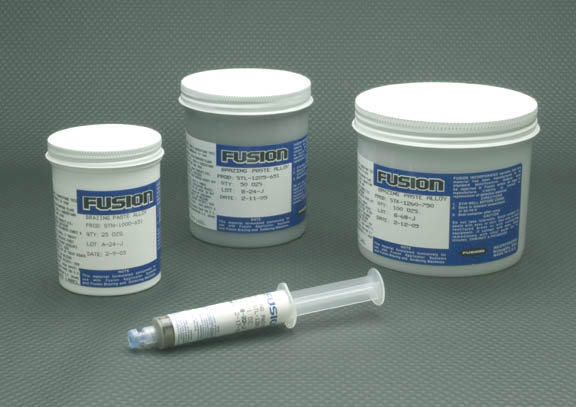

Silver brazing produces strong, sealed, leak-proof joints on. Silver brazing uses filler metals in solid form, like rings and wire, slugs, washers, powder, and paste. Proper brazements begin with a good joint design.

Silver brazing produces joints that meet specifications that meet mechanical performance, electrical conductivity, pressure tightness, corrosion resistance, and service temperature. High production, metal joining operations often employ silver brazing. Cadmium-free silver brazing alloys are available in paste form. Silver brazing is a popular method for joining or bonding ferrous and non-ferrous base metals like steel, stainless steel, copper, and brass. Silver brazing can be done on automatic machines for cost-efficient metal joining at high production rates.