Plumbing

The plumbing industry requires durable connections in its piping systems to prevent fluid loss and keep systems functioning optimally. Soldering is a longstanding metal-joining process that’s effective for creating such lasting joints between components, making it a good option for plumbing projects.

However, a durable soldered joint starts with using high-quality soldering alloys. At Fusion, Inc., our team understands the joint quality required for soldering plumbing components. Trust Fusion to deliver quality paste alloys and custom automation solutions for your plumbing industry application.

Soldering in the Plumbing Industry

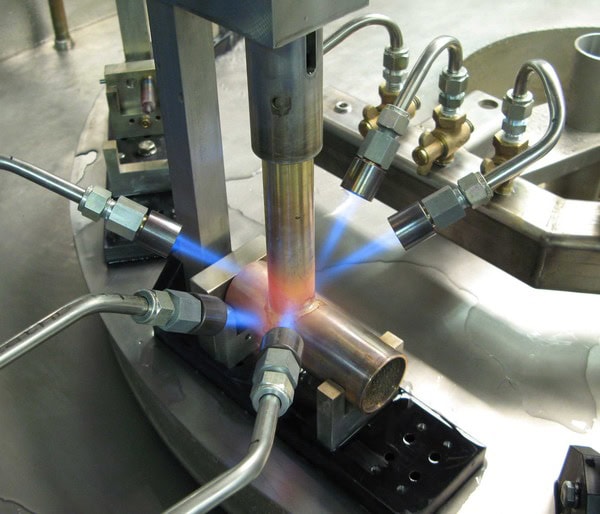

The soldering process creates a joint between two or more metal components using heat and filler metal, or solder, with a low melting point. Induction and flame are two common heat sources for the soldering process.

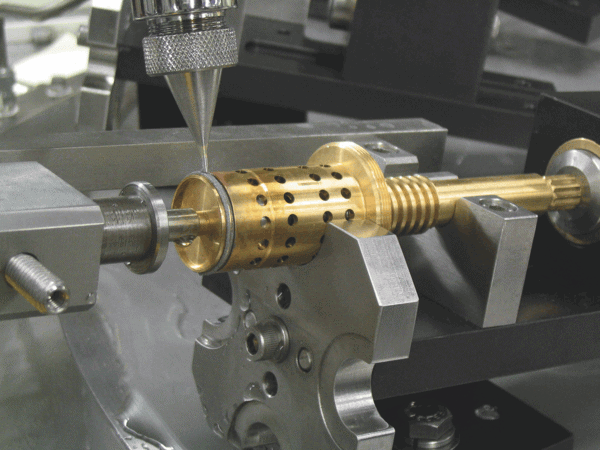

After placing solder at the location in which a pipe meets a fitting, valve, or various other connector, the process applies heat of less than 840°. The solder alloy will proceed to melt, flowing over the area and into the joint to permanently seal the components together. Despite the use of heat to generate this connection, however, soldering allows the base metals to maintain their integrity as the process won’t cause heat distortion.

As the alloy cools and solidifies, the result is a strong, leak-free joint connecting the base materials. The soldering technique is compatible with stainless steel, steel, brass, and copper, all of which are common metals for plumbing component manufacturing.

Common Plumbing Applications

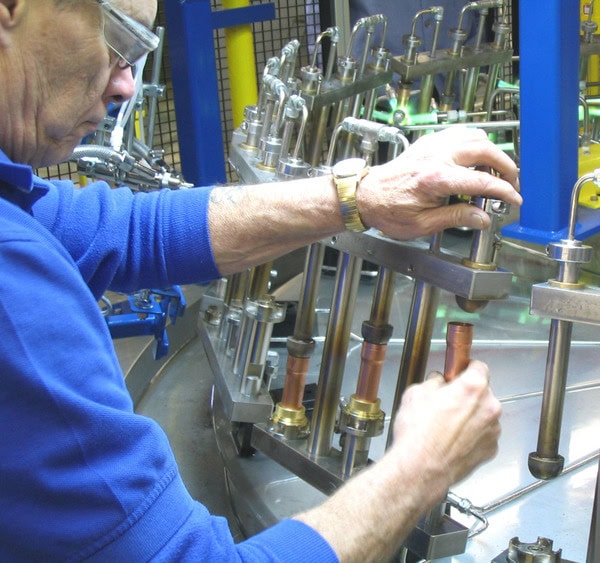

Soldering alloys are applicable in the plumbing industry to join components such as:

- Valves

- Valve assemblies

- Pipe fittings

- Adapters

- Faucets

- Drain parts

Advantages of Soldering for the Plumbing Industry

Soldering for plumbing applications is a good metal-joining technique for the industry for a number of reasons, including the following:

- Permanent and leak-free connections. As discussed, soldered joints are ideal for plumbing applications as they’re strong and will dependably prevent fluids like water from escaping a piping system or component.

- Affordability. Soldering doesn’t require specialized and expensive tools or crimp-type components. Instead, soldering can be performed with a simple heat system like a bottle torch, resulting in a low-cost process for creating reliable joints.

- Compatibility with low-pressure applications. Plumbing applications typically involve pressures less than or equal to 100 PSI. As such, a lesser joint strength between base metals is acceptable for plumbing components like valves and pipe fittings. Soldering is a good choice for achieving plumbing joints of sufficient strength and durability.

- Lower-temperature processing. Soldering doesn’t require operating temperatures as high as those for processes like brazing, so you can generate a soldered joint at lower heat settings without risking material deformation .

- Speed. Producing a soldered joint is a fast and efficient process, making it a technique that’s well-suited to industries like plumbing.

Plumbing Soldering Alloys From Fusion, Inc.

At Fusion, we offer the solder materials you need to create reliable, high-quality joints. Fusion’s soldering alloys are customized to meet your requirements for fast, single-step application, and eliminate the need to apply separate flux. Our custom-blended soldering paste readily adapts to parts of different sizes or shapes. A wide variety of formulations permit the joining of popular plumbing metals, including copper, brass, stainless steel, and steel.

Reach out to Fusion today to discuss your soldering alloy needs. Alternatively, are you looking to automate your soldering process? Request a consultation and let Fusion design and build you a solution! We aim to be a one-stop shop for all your process automation and soldering material requirements.